Our Digital Twin solution played a key role in helping the team plan smarter, keep things running smoothly, and carry out maintenance confidently even during major outages.

Here’s how DKI's Digital Twin was able to deliver real business value:

✅ Increased operational resilience

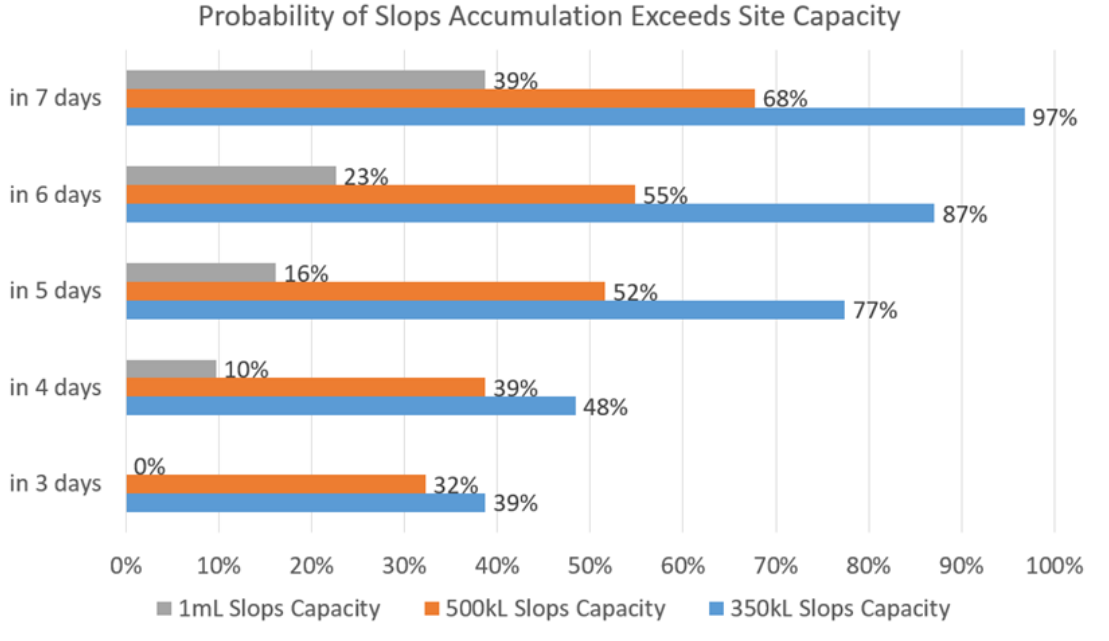

🔹Analysis of slops showed a terminal capacity of 7 days during busy period.

🔹Digital Twin modelling identified that increasing slops storage to 1 ML which will provide 17 days’ worth of storage enabling better operational resilience.

✅ Enabled zero-disruption maintenance

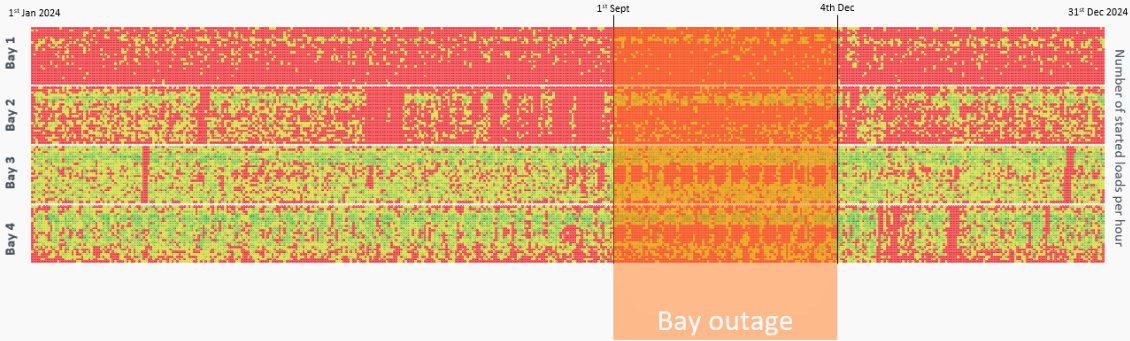

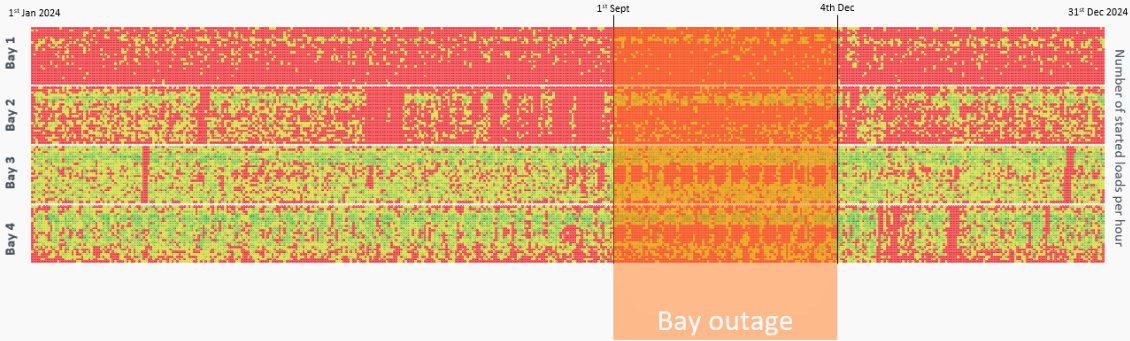

🔹Digital Twin was used to test various project strategies in order to cope with 3-month, 4-bay outage.

🔹More importantly, this project was putting critical jet loading operation at risk of disruption.

🔹Result: execution of predicted maintenance schedule was spot on resulting in no missed jet loads.

🔹DKI prediction for asset utilisation was 98.9% accurate!

✅ Uncovered hidden issues causing load disruption

🔹Root cause analysis of alarm data revealed 61% of Additive Clean Line Alarms are the result of E/OF interlock trips.

🔹5 tankers were worst offenders responsible for 27% of E/OF interlock trips which Digital Twin was able to identify letting the client target for inspection.

DKI’s Digital Twin assessed terminal uptime during slops gantry downtime, supporting the case to upgrade storage from 350kL to 1ML.

Don’t just take our word for it, here’s what the client had to say:

“Very helpful for us to assess gantry performance and a valuable tool in the near future when we carry out intrusive maintenance” – Engineering Manager, New Zealand fuel terminal client.

In 2024, Digital Twin guided a 3-month, 4-bay outage plan, predicting 44.9% bay use vs. 43.8% actual. Jet loading ran smoothly with zero disruption.

With new projects already underway for Q3 and Q4, we’re continuing to support this client and we’d be excited to do the same for you.