This innovation not only sets a new benchmark but also reinforces DKI’s role as a leader in advanced fueling solutions. Our Gas-Tight Vapour Coupler Hose delivers a range of benefits:

🔹 No other manufacturer offers this technology.

🔹 Allows drivers to operate safely without a breathing apparatus by fully sealing fuel vapours.

🔹 A game-changer in protecting frontline workers and raising industry safety standards.

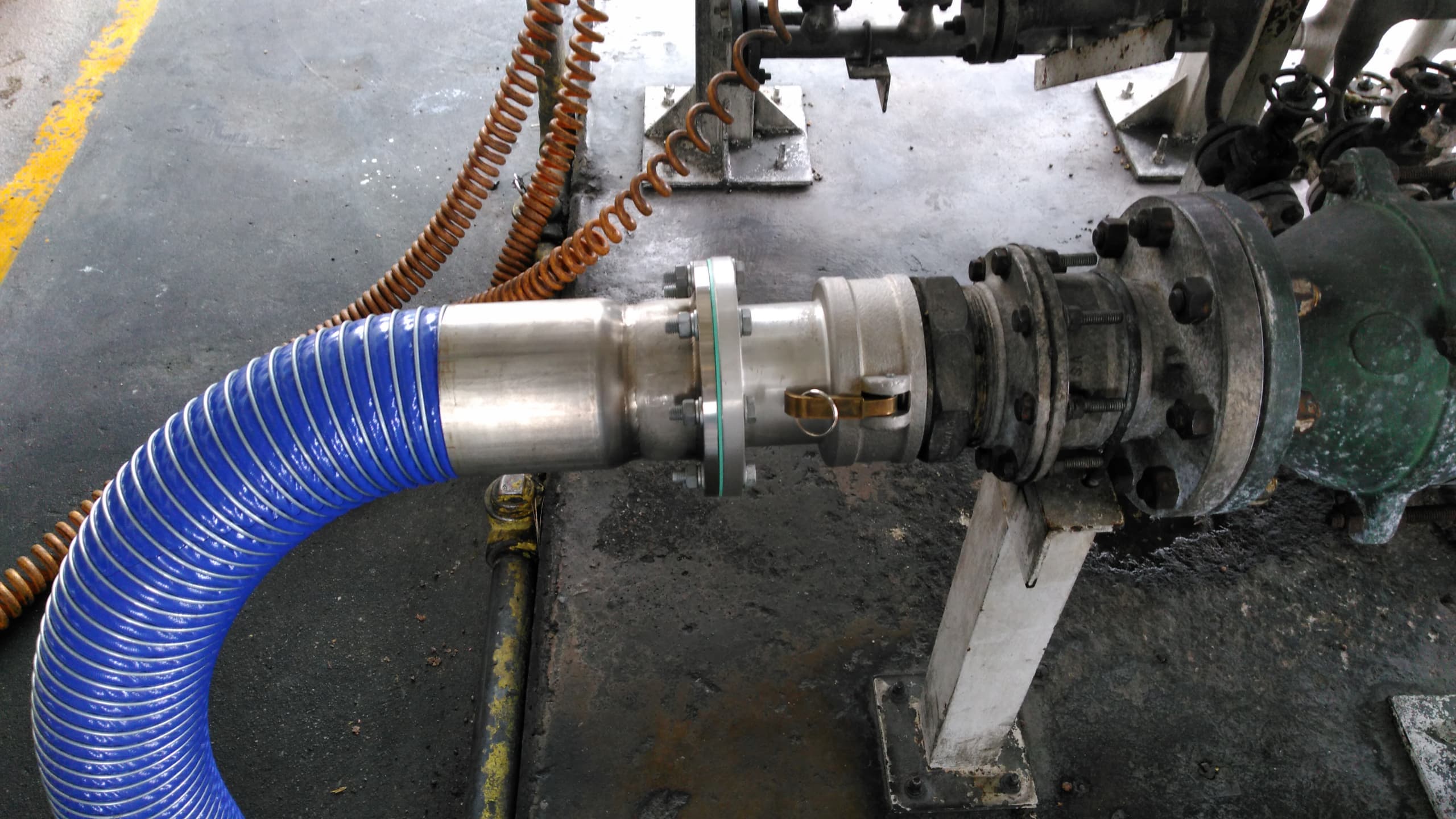

On Friday, 11 April 2025, we successfully conducted testing of our latest product at a major oil customer's largest terminal site in Malaysia by throughput, located in Selangor, in collaboration with the maintenance team. We are pleased to share that the terminal testing was completed smoothly, with all components performing as expected and meeting the required standards.

❇️How does this vapour coupler hose improve operational functionality and safety?

🔹Gas-tight hoses are designed to completely seal vapours, preventing the escape of fuel vapours. This is especially important in fuel handling or chemical transfer, where even small leaks can be hazardous or result in non-compliance with regulations.

🔹Gasoline vapours are highly flammable. A sealed vapour hose prevents the formation of flammable vapour clouds, significantly reducing the risk of fire or explosion in the work area.

🔹In systems where vapours are returned to the storage tank or captured, a gas-tight hose ensures the vapour loop is fully sealed, enhancing the efficiency and reliability of the entire recovery system.

🔹By reducing product loss and regulatory risk, and enhancing system performance, a gas-tight hose helps lower operational costs and long-term maintenance needs.